亮点

任务要求

应用范围

应用报告和下载

超出您的期待。

包装、传感器、解决方案。

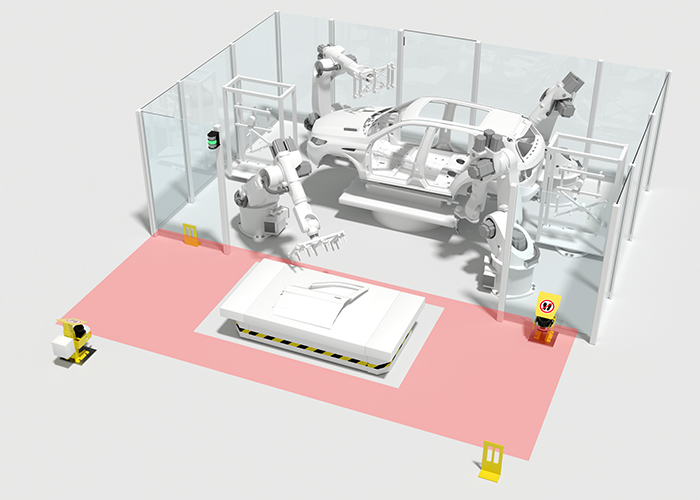

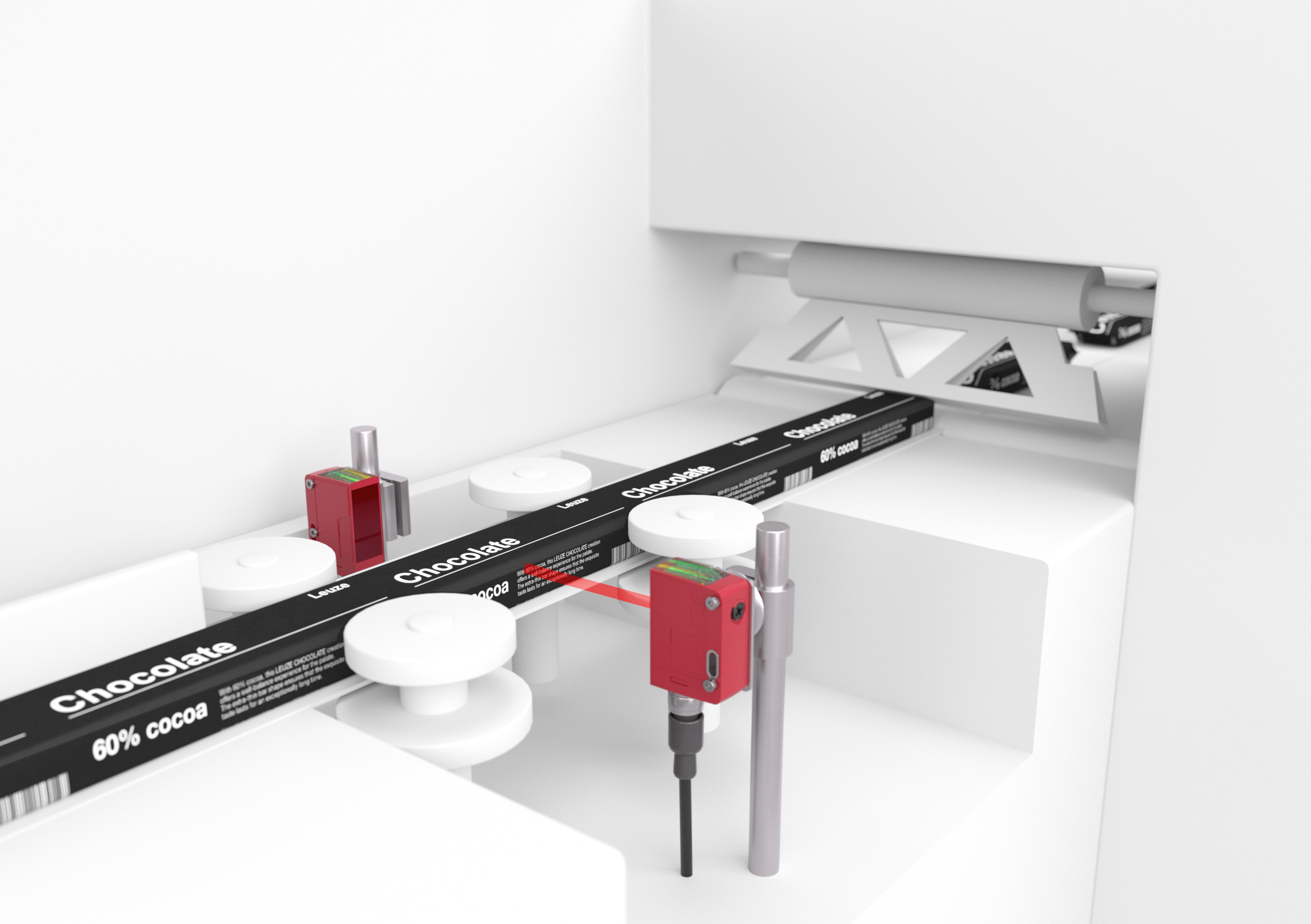

对包装机和消费品制造商的要求高,而且在不断变化:消费者期待具有创新性并且可持续的包装材料、品牌和消费者保护日益重要、电子商务成为零售业的大势所趋。食品和制药工业的包装过程必须越来越灵活、高效和智能。

我们广泛的产品组合包括适用于整个包装过程的传感器系统,能相应地满足您的特殊要求。香肠和奶酪加工或制药工业的卫生要求非常高,而饮料行业还格外注重速度和效率。在糖果包装中重要的是灵活性和格式更改简便。60 多年来,我们一直在与客户共同为各种应用开发合适的解决方案。无论是单个的标准传感器、特殊传感器还是整套解决方案。我们的目标是,保证您设备的可用性以及生产过程的可靠、故障安全和可追溯。

我们在食品和制药行业包装工艺方面的亮点

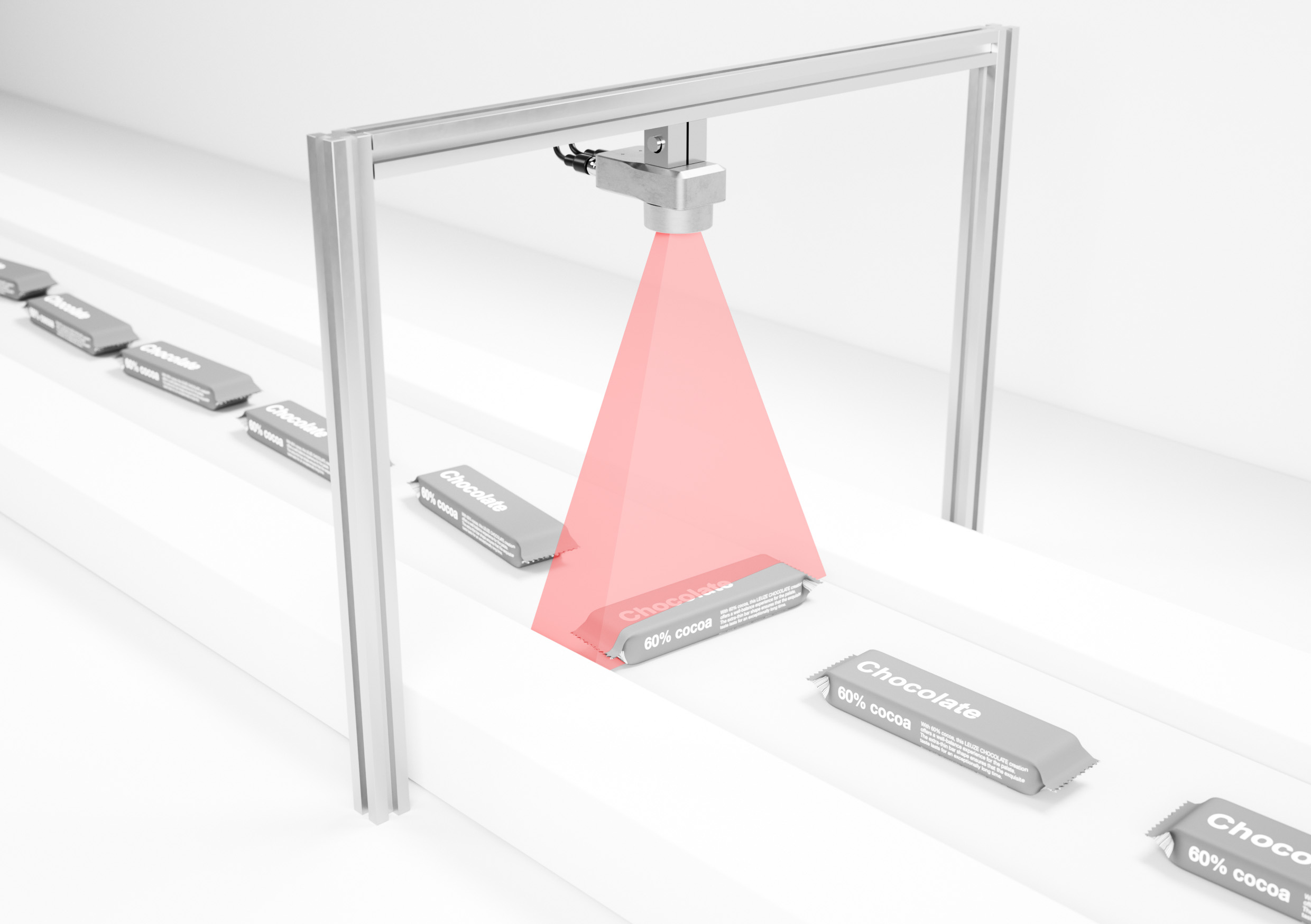

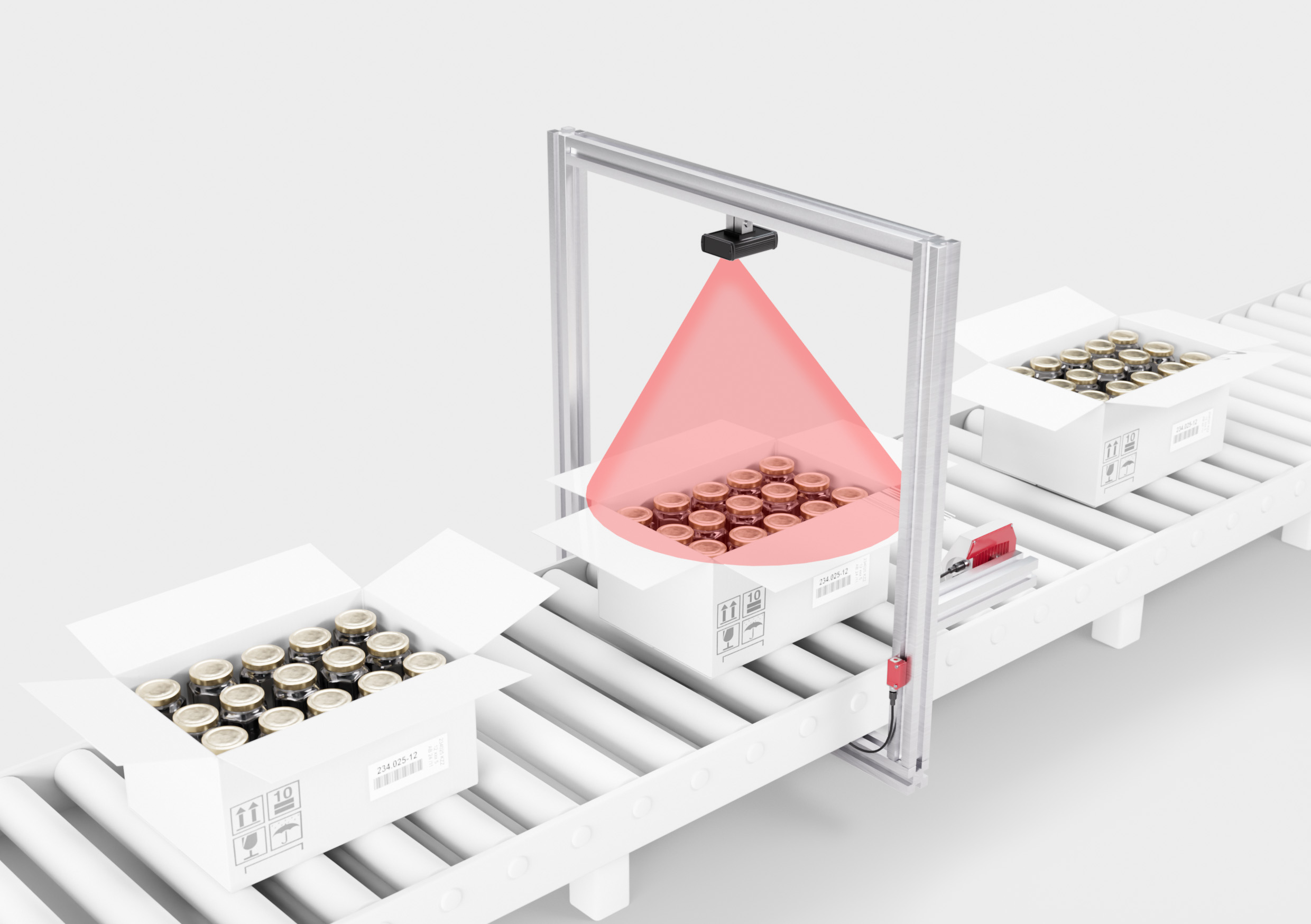

视觉传感器: IVS 108 和 IVS 1048i/DCR 1048i

功能可与视觉系统相媲美,使用起来却几乎如同光学传感器一样简单,这正是劳易测独特的视觉传感器的产品理念。新的产品组合实现了快速和简便地入门工业自动化中的图像处理。

新的传感器产品组合适用于有高度卫生要求的生产过程

我们全新的不锈钢传感器系列拥有采用 Hygienic 设计的 53C 系列和采用 Wash-Down设计的 55C 系列,专为有高度卫生要求的应用而开发。

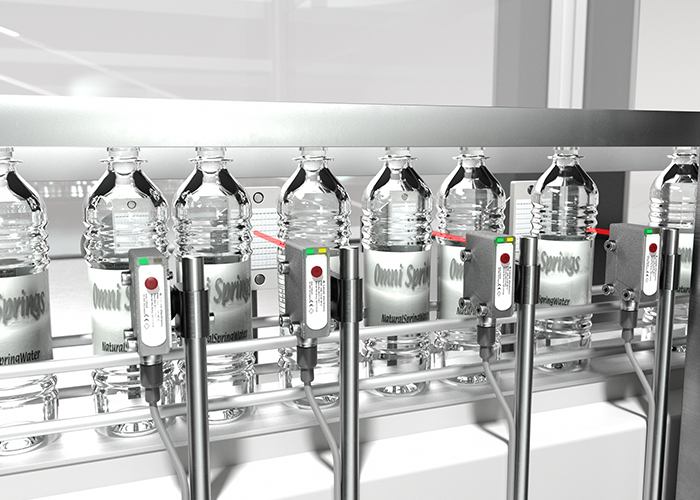

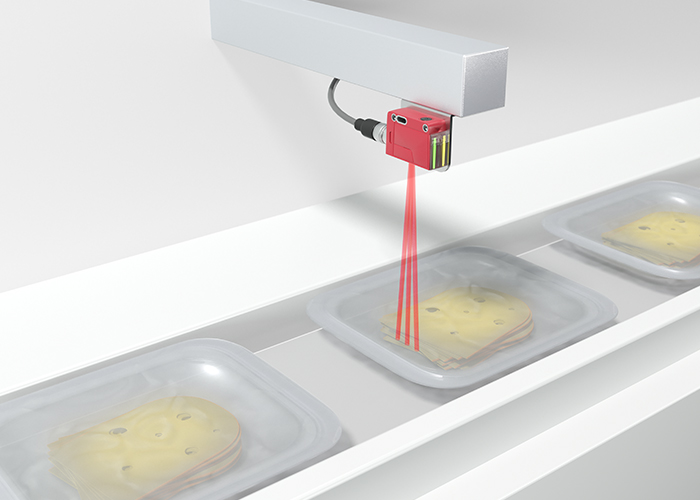

用于高透明物体的高速镜反射型光电传感器

PRK 18B 系列传感器能极其快速和可靠地识别出瓶坯、PET 瓶或玻璃瓶。特殊的跟踪功能可对污染进行补偿并延长清洁间隔。

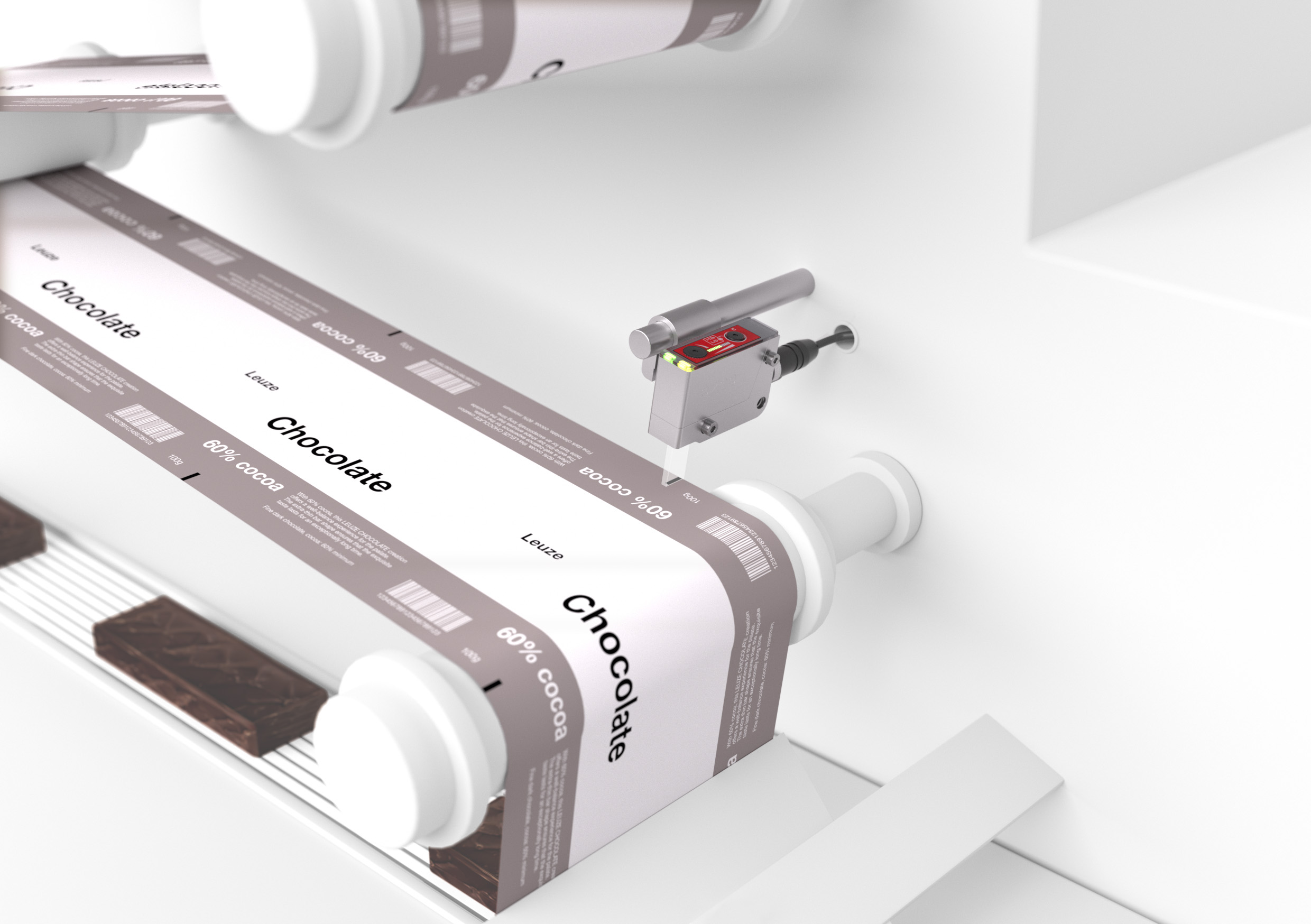

无关物体检测的动态参考传感器

该动态参考传感器 DRT 25C 配备有一项智能“对比度自适应示教”技术(CAT 技术),是识别疑难形状或表面的专家——无需在格式转换时调整传感器。

灵活和精确:超声波传感器,带有可调节声瓣

新的方形超声波传感器,具有小盲区和三个可调节声瓣宽度,可实现精确的开关和测量结果。

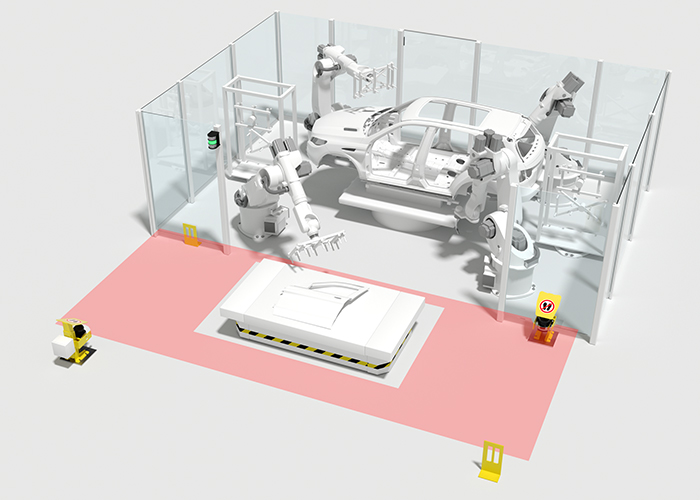

您的任务要求——我们的解决方案

食品和药品的加工和包装要求很高。我们为包装机制造商和消费品生产商提供传感器和应用咨询的支持。

应用范围

应用报告和下载

2023年10月1日

| 包装行业

When apples go swimming

2023年5月22日

| 包装行业

Best quality, non-stop

2023年3月10日

| 包装行业

A real piece of the ice age, bottled

2022年2月28日

| 包装行业

Increase productivity, reduce waste

2022年2月1日

| 包装行业

SN Maschinenbau: Three tasks, one visualization

2022年1月31日

| 包装行业

Quality is the number 1 key to success

2017年7月31日

| 包装行业